Premill and Pre-Milled Blanks for Dental Implants – Custom Titanium Solutions | DESS®

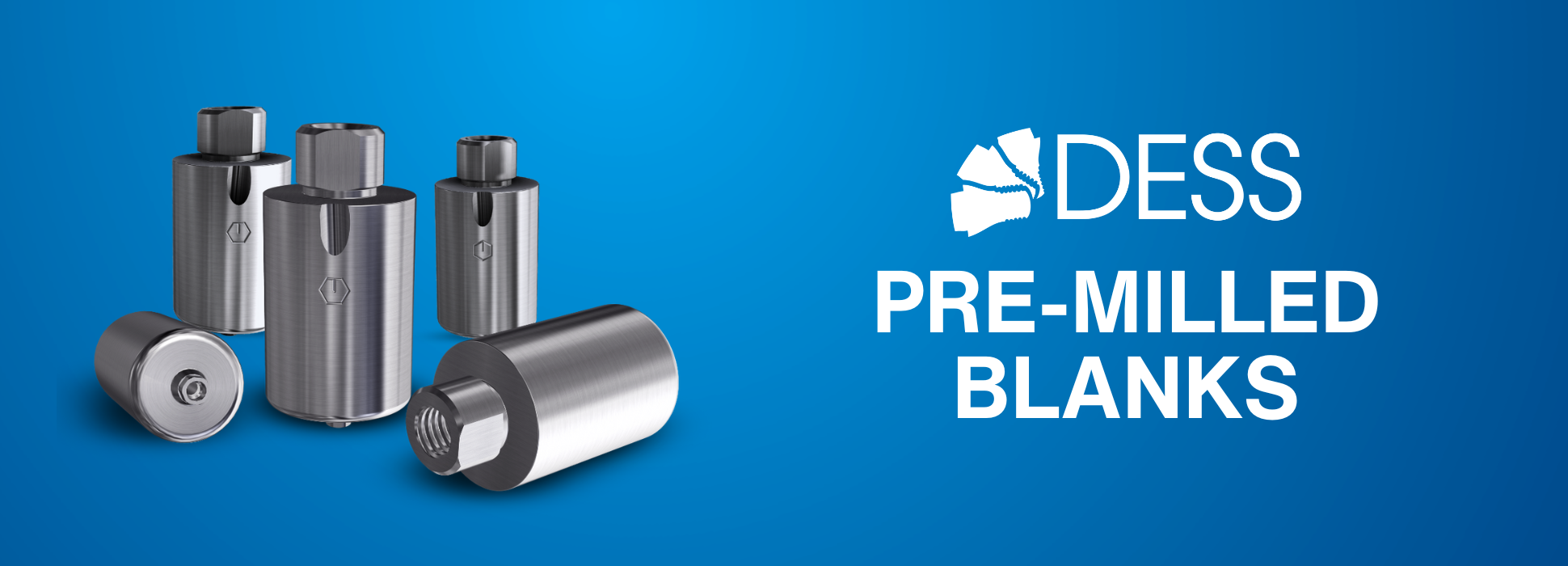

In digital dentistry, precision is non-negotiable—and every step in the workflow matters. Today’s dental professionals demand solutions that combine speed, accuracy, and full compatibility with modern implant systems. In response, DESS® introduces its new line of Pre-Milled Blanks: a smart solution engineered to deliver exceptional performance from the very first use. The DESS® Premill Blanks (Pre-milled Blanks) provide precision-milled titanium solutions for dental implant restorations.

DESS® Premill Blanks: Custom Titanium Precision for CAD/CAM Implant Restorations

Streamlined Integration with the Digital Workflow

The DESS® Pre-Milled Blanks are fully integrated into the DESS® Digital Dentistry Workflow, a comprehensive system that links every stage from CAD design to CAM manufacturing. These components are universally compatible with a wide range of leading implant systems, supporting a seamless and uninterrupted digital workflow without the need for complicated adjustments or adaptations.

Each pre-milled blank has been designed with millimetric precision to ensure a secure implant interface, optimal fit, and a smooth surface finish—ready for immediate integration into any digital production environment.

Key Advantages That Make a Difference

- Time and Cost Efficiency: The pre-machined implant connection significantly reduces milling time and optimizes lab production workflows.

- Universal compatibility: Available for a wide range of implant platforms, offering clinicians and labs maximum flexibility.

- Reliable, Repeatable Outcomes: Each component meets the exacting quality and precision standards that define DESS® products.

- Reliable fit and precision: the Pre-milled connection ensures stable and accurate prosthetic connections.

- Exclusive “Pull down and lock” fixation system: This proprietary feature guarantees secure and accurate positioning of the blank within the milling holder.

- Certified Digital Workflow Support: part of the certified DESS® digital workflow, with full regulatory compliance and technical assistance. As part of the DESS® Digital Workflow, these blanks are backed by regulatory compliance and full technical support.

The Ideal Solution for Modern Dental Labs

DESS® Pre-Milled Blanks are specifically designed for dental labs and milling centres looking to increase efficiency without compromising precision or final prosthetic quality. Their use streamlines the fabrication of customized abutments and restorations, reducing turnaround times and adding value for both clinicians and patients.

Whether for single-unit restorations or—coming soon—multi-unit prostheses, DESS® Pre-Milled Blanks offer a unique combination of precision, durability, and optimal milling performance.

DESS® Pre-Milled Blanks represent the future of implant customization. With their practical design, proven reliability, and seamless integration within the DESS® digital ecosystem, they provide a forward-thinking solution for a more efficient and precise restorative workflow. Discover more on our website.

If you need more information about DESS® Pre-milled Blanks, don’t hesitate to contact our team by calling +34 900 828 009 or emailing info@dessdental.com.